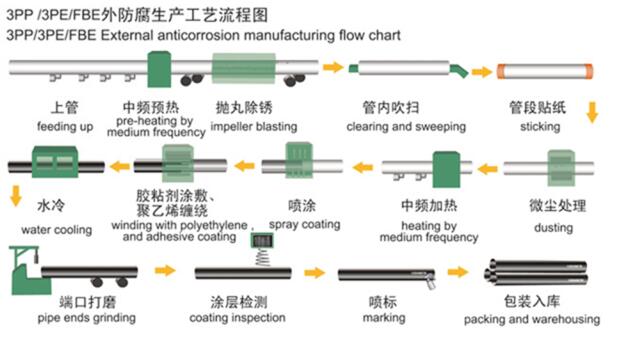

The outer wall of steel pipe anticorrosion line main process (this is the whole line process flow diagram, composed the line 1 to 11)

Equipment is briefly

1、Steel pipe conveyor line:

Steel pipe conveying equipment is mainly used for conveying pipe, it has a steel tube line transportation equipment and two categories of screw conveyor equipment, steel pipe line conveyor equipment is mainly used in the steel pipe from the process to the next working procedure and the transition of steel pipe conveying; And steel pipe screw conveyor mainly is the need of anticorrosion production process, steel tube in the process of production Forward, while rotating spiral transporting tubes, thus accomplishes the descaling and surface coated steel pipe.

2、Steel pipe heating equipment

Steel pipe heating equipment technical requirements for steel pipe, steel pipe for heating, according to different technical requirements for steel pipe preheating, heating and solidification.

3、Steel pipe preheating equipment

Steel pipe used for preheating system before blast cleaning of steel tube heated to a temperature of 40 ℃ to 60 ℃, remove the surface moisture, moisture and oil, derusting quality in order to get to meet the requirements.

Steel pipe preheating can be used in a heating furnace and intermediate frequency preheating (see medium frequency heating), and can use natural gas and diesel combustion furnace heating two kinds of medium.

4、Steel pipe heating equipment

Steel pipe heating of intermediate frequency heating using the electromagnetic induction principle, in front of the coated steel pipe heated to 180 ℃, 230 ℃, in order to achieve the demand of the powder coating and coating process。

5、Steel pipe purging equipment

Pipe purging system is used to use the fan to the inside of the steel tube dust, clean up the steel grit steel shot, to prevent pollution in the coating process and coating steel pipe surface. By the pipe blowing dust, dust collecting box, car back pulse dust catcher, lift rotating roller, block tube device, etc. On the dust collecting box is equipped with a filter cartridge back pulse dust catcher.

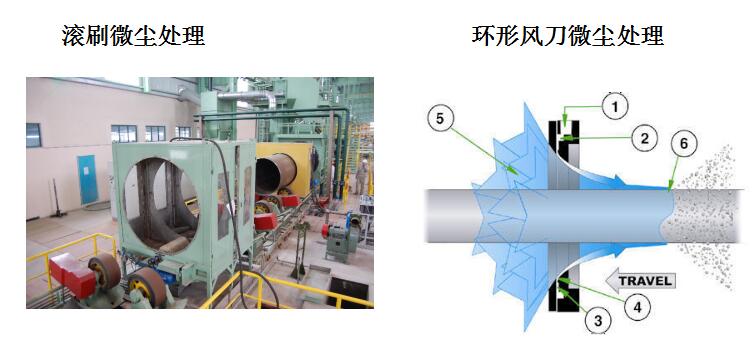

6、Dust treatment

Dust treatment is clean up after the steel pipe shot blasting derusting, the dust adhered on the surface of the steel tube and abrasive, improve FBE adhesive power, and can prevent steel tube be affected with damp be affected with damp and secondary rust < b > (using compressed air knife or nylon roller two kinds of processing mode)。

7、Epoxy powder coating and recovery system

Steel pipe epoxy powder spraying adopts high voltage electrode built-in spray gun, through the generation of high voltage electrostatic epoxy resin powder evenly sprayed to the surface of steel after heating, after curing epoxy powder coating.

Epoxy powder coating and recovery system made of stainless steel coating chamber, epoxy powder spraying, powder spraying controller, fluidization for powder box, double cyclone collecting tower and back pulse of cartridge filter.

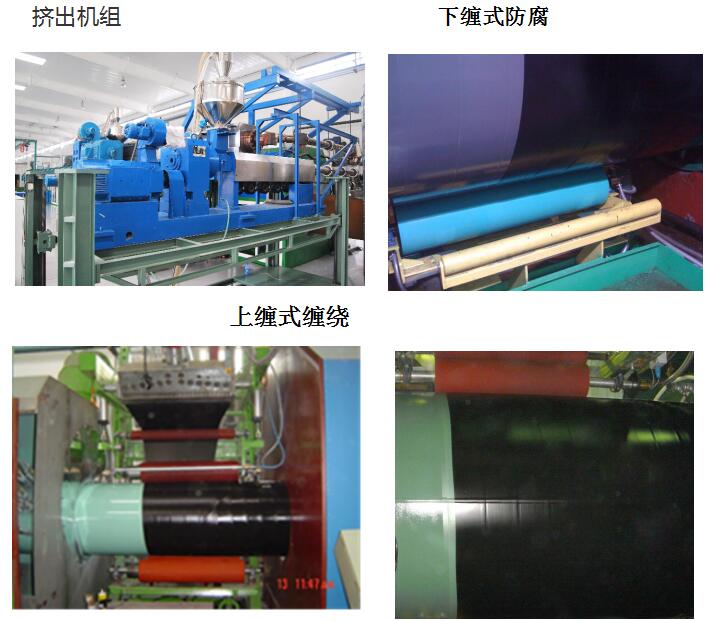

8、PE extruder system

Used for the extrusion and PE adhesive and PE protective layer winding (or covered) in steel tube outer wall and the when not completely cured epoxy powder coating and then wrapped a layer of adhesives winding protective layer, a layer of polyethylene (polypropylene) finally reached on the surface of steel pipe anticorrosion and protection.

There are wrapped in steel pipe in the production of 3 PE anticorrosive type and coated type two kinds big, and the spiral wound is divided into two ways: there are two main ways winding way, a kind of stove for mold, another is mould offset type.

9、Steel pipe cooling spray equipment

Water cooling system is mainly used for tube rapid cooling after hot coating to 40 ℃ to 60 ℃. Ensure that after coating anticorrosive layer and protective layer is not been hurt. Circulating water cooling system by water cooling room, cooling tower, self-priming pumps, centrifugal pumps and piping, near the cooling room is equipped with back to the pool。

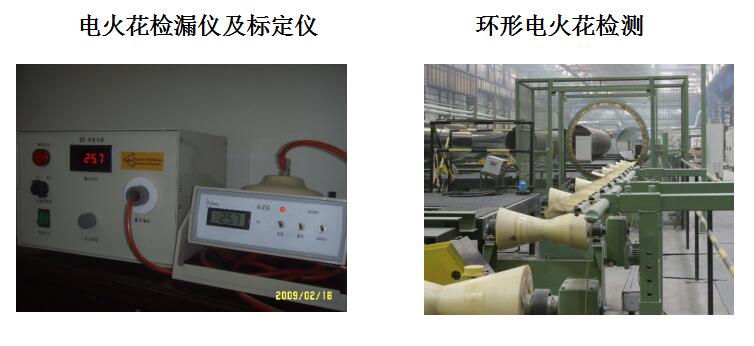

10、Electric spark testing equipment

Used for detection of steel pipe anticorrosion layers after coating, and to deal with the detection funnelled. Ensure the quality of the coated steel pipe factory。

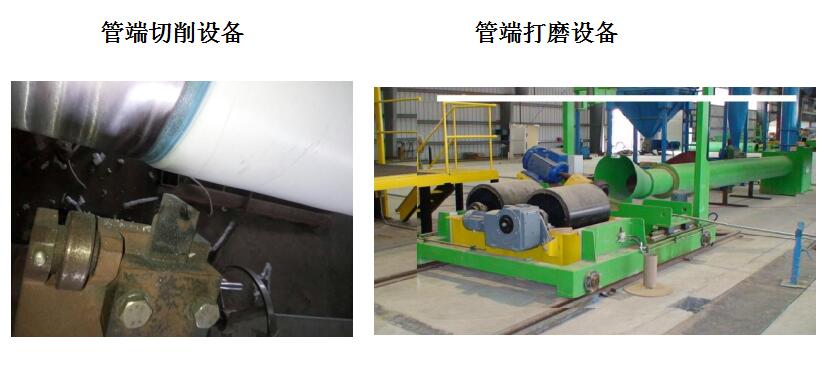

11、The finished tube tube processing equipment

Pipe cutting (grinding) equipment is used for removing coating at the ends of the pipe coating in accordance with the requirements, and the coating face form 15 to 45 degrees and the groove, facilitate the pipe construction at the scene.

Pipe cutting device is a new type of pipe processing equipment, the maximum cutting length can be up to 600 mm, and the device itself six direction is adjustable, can adapt to a wide range of pipe diameter, the equipment without destroying powder can according to the requirements under the premise of complete removal of the surface of PE and adhesives and has the advantages of low noise, little pollution.

Pipe end grinding pause with single head or double efficient grinding machine, the host polished steel wire brush, grinding machine, mobile car, the secondary grinding head stand walking, high efficiency of dust collector, and supporting lift rotating roller, block pipe double rocker and other auxiliary equipment.